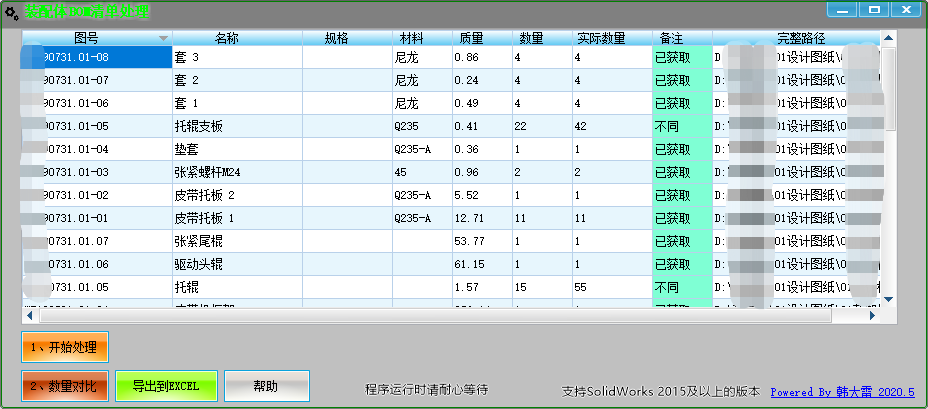

由于个人XX,目前会使用SolidWorks,需要加工的模型要出工程图,而模型中的“数量”这个属性是由手工添加进去的,这就导致了可能出现手工填写出错的情况。如果某个零件只需要1个,结果不小心写成了2个,一旦东西做出来之后心里会有一万只草泥马在奔腾了吧。所以我秉承着没有工具就自己做,能动手就少BB的思想,决定开发一个功能,来自动检查模型中的“数量”这个属性是否有误,一劳永逸的解决这个问题,提高设计的准确率。

思路如下:获取总装配体中所有零件的BOM,这个BOM应该是完全正确的,因为你装配了多少零部件进去,这个BOM中的量就是多少。然后再逐一获取每个零件中的“数量”这个属性,并进行对比,对比后将结果导出为EXCEL,以供查询。

这里我采用的是遍历整个装配体的方式来获取BOM,不好意思,这一段核心代码我真的是在书上抄的,感谢 SOLIDWORKS API二次开发实例详解(微视频版)这本书,有兴趣的同学可以买一本,要支持正版啊,鄙视白嫖!

public void TraverseFeature(ModelDoc2 Modle, Dictionary<string, BomBean> BomDic, Dictionary<string, int> PartCountDic)//顶层部件

{

FeatureManager FM = Modle.FeatureManager;

Feature swFeat = Modle.FirstFeature();

CustomPRopertyManager CPM;

string FileNameNoExt = "";

int PartNoInNowLevetl = 1;//当前层级下的件号

while (swFeat != null)

{

object ObjComp = swFeat.GetSpecificFeature2();

if (ObjComp is Component2)

{

Component2 Comp = (Component2)ObjComp;

if (Comp.ExcludeFromBOM == true || Comp.GetSuppression() == 0)//压缩或排除在明细表外的部件

{

swFeat = swFeat.GetNextFeature();

continue;

}

else if (Comp.GetSuppression() == 1 || Comp.GetSuppression() == 3 || Comp.GetSuppression() == 4)//轻化

{

Comp.SetSuppression2(2);//全部还原

}

ModelDoc2 SubModle = Comp.GetModelDoc2();

CPM = SubModle.Extension.CustomPropertyManager[""];

FileNameNoExt = SubModle.GetTitle().Substring(0, SubModle.GetTitle().LastIndexOf("."));

if (Comp.IsPatternInstance())//是镜像阵列之类的

{

if (PartCountDic.ContainsKey(FileNameNoExt))

{

PartCountDic[FileNameNoExt] = PartCountDic[FileNameNoExt] + 1;

}

else

{

PartCountDic.Add(FileNameNoExt, 1);

}

swFeat = swFeat.GetNextFeature();

continue;

}

#region 登记零件信息

BomBean bb = new BomBean();

bb.DwgNo = GetBomInfo(CPM, "代号");

bb.PartName = GetBomInfo(CPM, "名称");

bb.Material = GetBomInfo(CPM, "规格");

//bb.PreMass = double.Parse(GetBomInfo(CPM, "单重"));

bb.Remark = GetBomInfo(CPM, "备注");

bb.FileNameNoExt = FileNameNoExt;

bb.pathname = Comp.GetPathName();

BomDic.Add(PartNoInNowLevetl.ToString().Trim(), bb);

#endregion

if (SubModle.GetType() == (int)swDocumentTypes_e.swDocASSEMBLY)//说明是装配体//开分进程扫描子装配

{

TraverseComp(Comp, BomDic, PartNoInNowLevetl.ToString().Trim(), PartCountDic, CPM);

}

PartNoInNowLevetl = PartNoInNowLevetl + 1;

}

swFeat = swFeat.GetNextFeature();

}

}

public void TraverseComp(Component2 Comp, Dictionary<string, BomBean> BomDic, string ParentPartNo, Dictionary<string, int> PartCountDic, CustomPropertyManager CPM)// 这个是扫描子部件,TopPbb是相对的顶层,StdDwg=true,是标准图

{

Feature swFeat = Comp.FirstFeature();

int PartNoInNowLevetl = 1;//当前层级下的件号

string FileNameNoExt = "";

while (swFeat != null)

{

object ObjComp = swFeat.GetSpecificFeature2();

if (ObjComp is Component2)

{

Component2 Comp1 = (Component2)ObjComp;

if (Comp1.ExcludeFromBOM == true || Comp1.GetSuppression() == 0)//压缩或排除在明细表外的部件

{

swFeat = swFeat.GetNextFeature();

continue;

}

else if (Comp1.GetSuppression() == 1 || Comp1.GetSuppression() == 3 || Comp1.GetSuppression() == 4)//轻化

{

Comp1.SetSuppression2(2);//全部还原

}

ModelDoc2 SubModle = Comp1.GetModelDoc2();

CPM = SubModle.Extension.CustomPropertyManager[""];

FileNameNoExt = SubModle.GetTitle().Substring(0, SubModle.GetTitle().LastIndexOf("."));

if (Comp.IsPatternInstance())//是镜像阵列之类的

{

if (PartCountDic.ContainsKey(FileNameNoExt))

{

PartCountDic[FileNameNoExt] = PartCountDic[FileNameNoExt] + 1;

}

else

{

PartCountDic.Add(FileNameNoExt, 1);

}

swFeat = swFeat.GetNextFeature();

continue;

}

#region 登记零件信息

BomBean bb = new BomBean();

bb.DwgNo = GetBomInfo(CPM, "代号");

bb.PartName = GetBomInfo(CPM, "名称");

bb.Material = GetBomInfo(CPM, "规格");

//bb.PreMass = double.Parse(GetBomInfo(CPM, "单重"));

bb.Remark = GetBomInfo(CPM, "备注");

bb.pathname = Comp1.GetPathName();

bb.FileNameNoExt = FileNameNoExt;

BomDic.Add(ParentPartNo + "-" + PartNoInNowLevetl.ToString().Trim(), bb);

#endregion

if (SubModle.GetType() == (int)swDocumentTypes_e.swDocASSEMBLY)//说明是装配体//开分进程扫描子装配

{

TraverseComp(Comp1, BomDic, ParentPartNo + "-" + PartNoInNowLevetl.ToString().Trim(), PartCountDic, CPM);

}

PartNoInNowLevetl = PartNoInNowLevetl + 1;

}

swFeat = swFeat.GetNextFeature();

}

}成品的效果如下:

后续因要考虑数量获取的各种干扰因素,烂尾中……